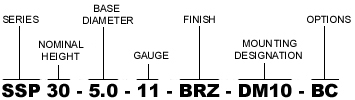

CATALOG LOGIC - ORDERING SAMPLE

|

|

|

Catalog Number

|

Nominal

Height

|

Pole Shaft

|

Gauge

|

Handhole

Size

|

Anchor Bolt

|

Bolt

Circle

|

80

MPH

|

90

MPH

|

100

MPH

|

Ship

WT.

|

Select

|

| SSP10-4.0-11 | 10 | 4.0 x 10.0 | 11 | 3 x 5 | 0.75 x 17 x 3 | 8 | 42.1 | 33.5 | 27.1 | 87 | Configure | | SSP10-4.0-7 | 10 | 4.0 x 10.0 | 7 | 3 x 5 | 0.75 x 30 x 3 | 8 | 55 | 44 | 35.5 | 130 | Configure | | SSP10-5.0-11 | 10 | 5.0 x 10.0 | 11 | 3 x 5 | 1.00 x 36 x 4 | 11 | 58 | 44 | 34 | 151 | Configure | | SSP12-4.0-11 | 12 | 4.0 x 12.0 | 11 | 3 x 5 | 0.75 x 17 x 3 | 8 | 33.7 | 26.7 | 21.4 | 100 | Configure | | SSP12-4.0-7 | 12 | 4.0 x 12.0 | 7 | 3 x 5 | 0.75 x 30 x 3 | 8 | 47.5 | 37.3 | 29.8 | 150 | Configure | | SSP12-5.0-11 | 12 | 5.0 x 12.0 | 11 | 3 x 5 | 1.00 x 36 x 4 | 11 | 49 | 38 | 29 | 168 | Configure | | SSP14-4.0-11 | 14 | 4.0 x 14.0 | 11 | 3 x 5 | 0.75 x 17 x 3 | 8 | 27.4 | 21.5 | 17.1 | 113 | Configure | | SSP14-4.0-7 | 14 | 4.0 x 14.0 | 7 | 3 x 5 | 0.75 x 30 x 3 | 8 | 40 | 31 | 24.5 | 170 | Configure | | SSP14-5.0-11 | 14 | 5.0 x 14.0 | 11 | 3 x 5 | 1.00 x 36 x 4 | 11 | 40 | 30 | 23 | 184 | Configure | | SSP14-5.0-7 | 14 | 5.0 x 14.0 | 7 | 3 x 5 | 1.00 x 36 x 4 | 11 | 65 | 52 | 41.5 | 242 | Configure | | SSP15-4.0-11 | 15 | 4.0 x 15.0 | 11 | 3 x 5 | 0.75 x 17 x 3 | 8 | 20.7 | 16.1 | 12.6 | 119 | Configure | | SSP15-4.0-7 | 15 | 4.0 x 15.0 | 7 | 3 x 5 | 0.75 x 30 x 3 | 8 | 30.9 | 24.4 | 19.6 | 172 | Configure | | SSP15-5.0-11 | 15 | 5.0 x 15.0 | 11 | 3 x 5 | 1.00 x 36 x 4 | 11 | 36 | 27.5 | 21 | 192 | Configure | | SSP15-5.0-7 | 15 | 5.0 x 15.0 | 7 | 3 x 5 | 1.00 x 36 x 4 | 11 | 59 | 46.5 | 37 | 254 | Configure | | SSP16-4.0-11 | 16 | 4.0 x 16.0 | 11 | 3 x 5 | 0.75 x 17 x 3 | 8 | 18.7 | 14.4 | 11.2 | 125 | Configure | | SSP16-4.0-7 | 16 | 4.0 x 16.0 | 7 | 3 x 5 | 0.75 x 30 x 3 | 8 | 27.2 | 20.7 | 16 | 210 | Configure | | SSP16-5.0-11 | 16 | 5.0 x 16.0 | 11 | 3 x 5 | 1.00 x 36 x 4 | 11 | 33.5 | 25 | 18 | 201 | Configure | | SSP16-5.0-7 | 16 | 5.0 x 16.0 | 7 | 3 x 5 | 1.00 x 36 x 4 | 11 | 54 | 43 | 34 | 266 | Configure | | SSP18-4.0-11 | 18 | 4.0 x 18.0 | 11 | 3 x 5 | 0.75 x 17 x 3 | 8 | 15.2 | 11.5 | 8.7 | 138 | Configure | | SSP18-4.0-7 | 18 | 4.0 x 18.0 | 7 | 3 x 5 | 0.75 x 30 x 3 | 8 | 27.2 | 20.7 | 16 | 210 | Configure | | SSP18-5.0-11 | 18 | 5.0 x 18.0 | 11 | 3 x 5 | 1.00 x 36 x 4 | 11 | 27 | 19.5 | 15 | 218 | Configure | | SSP18-5.0-7 | 18 | 5.0 x 18.0 | 7 | 3 x 5 | 1.00 x 36 x 4 | 11 | 46 | 36 | 28 | 291 | Configure | | SSP20-4.0-11 | 20 | 4.0 x 20.0 | 11 | 3 x 5 | 0.75 x 17 x 3 | 8 | 12.3 | 9 | 6.5 | 151 | Configure | | SSP20-4.0-7 | 20 | 4.0 x 20.0 | 7 | 3 x 5 | 0.75 x 30 x 3 | 8 | 19.6 | 15 | 11.5 | 219 | Configure | | SSP20-5.0-11 | 20 | 5.0 x 20.0 | 11 | 3 x 5 | 1.00 x 36 x 4 | 11 | 22.2 | 16.8 | 12.6 | 235 | Configure | | SSP20-5.0-7 | 20 | 5.0 x 20.0 | 7 | 3 x 5 | 1.00 x 36 x 4 | 11 | 35.4 | 27.5 | 21.5 | 313 | Configure | | SSP20-6.0-7 | 20 | 6.0 x 20.0 | 7 | 3 x 5 | 1.00 x 36 x 4 | 11.5 | 56 | 42.5 | 33.5 | 368 | Configure | | SSP22-4.0-11 | 22 | 4.0 x 22.0 | 11 | 3 x 5 | 0.75 x 17 x 3 | 8 | 6.9 | 4.3 | 2.3 | 182 | Configure | | SSP22-4.0-7 | 22 | 4.0 x 22.0 | 7 | 3 x 5 | 0.75 x 30 x 3 | 8 | 12.2 | 8.7 | 6 | 266 | Configure | | SSP22-5.0-11 | 22 | 5.0 x 22.0 | 11 | 3 x 5 | 1.00 x 36 x 4 | 11 | 18.5 | 13.6 | 9.8 | 252 | Configure | | SSP22-5.0-7 | 22 | 5.0 x 22.0 | 7 | 3 x 5 | 1.00 x 36 x 4 | 11 | 30.2 | 23.2 | 17.8 | 337 | Configure | | SSP22-6.0-7 | 22 | 6.0 x 22.0 | 7 | 3 x 5 | 1.00 x 36 x 4 | 11.5 | 49 | 37.5 | 28 | 398 | Configure | | SSP24-4.0-7 | 24 | 4.0 x 24.0 | 7 | 3 x 5 | 0.75 x 30 x 3 | 8 | 12.2 | 8.7 | 6 | 266 | Configure | | SSP24-5.0-11 | 24 | 5.0 x 24.0 | 11 | 3 x 5 | 1.00 x 36 x 4 | 11 | 15.2 | 10.8 | 7.4 | 268 | Configure | | SSP24-5.0-7 | 24 | 5.0 x 24.0 | 7 | 3 x 5 | 1.00 x 36 x 4 | 11 | 25.8 | 19.4 | 14.6 | 361 | Configure | | SSP24-6.0-7 | 24 | 6.0 x 24.0 | 7 | 3 x 5 | 1.00 x 36 x 4 | 11.5 | 42 | 31.5 | 23 | 428 | Configure | | SSP25-4.0-11 | 25 | 4.0 x 25.0 | 11 | 3 x 5 | 0.75 x 17 x 3 | 8 | 6.9 | 4.3 | 2.3 | 182 | Configure | | SSP25-4.0-7 | 25 | 4.0 x 25.0 | 7 | 3 x 5 | 0.75 x 30 x 3 | 8 | 12.2 | 8.7 | 6 | 266 | Configure | | SSP25-5.0-11 | 25 | 5.0 x 25.0 | 11 | 3 x 5 | 1.00 x 36 x 4 | 11 | 13.8 | 9.5 | 6.3 | 276 | Configure | | SSP25-5.0-7 | 25 | 5.0 x 25.0 | 7 | 3 x 5 | 1.00 x 36 x 4 | 11 | 23.8 | 17.7 | 13.1 | 373 | Configure | | SSP25-6.0-7 | 25 | 6.0 x 25.0 | 7 | 3 x 5 | 1.00 x 36 x 4 | 11.5 | 39 | 28.5 | 21 | 443 | Configure | | SSP26-4.0-7 | 26 | 4.0 x 26.0 | 7 | 3 x 5 | 0.75 x 30 x 3 | 8 | 6.9 | 4 | 1 | 312 | Configure | | SSP26-5.0-11 | 26 | 5.0 x 26.0 | 11 | 3 x 5 | 1.00 x 36 x 4 | 11 | 12.4 | 8.3 | 5.2 | 284 | Configure | | SSP26-5.0-7 | 26 | 5.0 x 26.0 | 7 | 3 x 5 | 1.00 x 36 x 4 | 11 | 21.9 | 16.1 | 11.8 | 384 | Configure | | SSP26-6.0-7 | 26 | 6.0 x 26.0 | 7 | 3 x 5 | 1.00 x 36 x 4 | 11.5 | 35.5 | 25.5 | 18.5 | 457 | Configure | | SSP28-4.0-7 | 28 | 4.0 x 28.0 | 7 | 3 x 5 | 0.75 x 30 x 3 | 8 | 6.9 | 4 | 1 | 312 | Configure | | SSP28-5.0-11 | 28 | 5.0 x 28.0 | 11 | 3 x 5 | 1.00 x 36 x 4 | 11 | 9.8 | 6.1 | 3.2 | 300 | Configure | | SSP28-5.0-7 | 28 | 5.0 x 28.0 | 7 | 3 x 5 | 1.00 x 36 x 4 | 11 | 18.4 | 13.2 | 9.2 | 408 | Configure | | SSP28-6.0-7 | 28 | 6.0 x 28.0 | 7 | 3 x 5 | 1.00 x 36 x 4 | 11.5 | 30 | 21.5 | 15 | 487 | Configure | | SSP30-4.0-7 | 30 | 4.0 x 30.0 | 7 | 3 x 5 | 0.75 x 30 x 3 | 8 | 6.9 | 4 | 1 | 312 | Configure | | SSP30-5.0-11 | 30 | 5.0 x 30.0 | 11 | 3 x 5 | 1.00 x 36 x 4 | 11 | 6.5 | 3.5 | 1.2 | 315 | Configure | | SSP30-5.0-7 | 30 | 5.0 x 30.0 | 7 | 3 x 5 | 1.00 x 36 x 4 | 11 | 13.4 | 9.1 | 5.9 | 432 | Configure | | SSP30-6.0-7 | 30 | 6.0 x 30.0 | 7 | 3 x 5 | 1.00 x 36 x 4 | 11.5 | 27.5 | 19.9 | 14.1 | 512 | Configure | | SSP30-6.0-3 | 30 | 6.0 x 30.0 | 3 | 3 x 5 | 1.00 x 36 x 4 | 12 | 34.3 | 25.3 | 18.5 | 645 | Configure | | SSP35-5.0-7 | 35 | 5.0 x 35.0 | 7 | 3 x 5 | 1.00 x 36 x 4 | 11 | 7.2 | 3.7 | 1 | 491 | Configure | | SSP35-6.0-7 | 35 | 6.0 x 35.0 | 7 | 3 x 5 | 1.00 x 36 x 4 | 11.5 | 15 | 9.5 | 5.3 | 584 | Configure | | SSP35-6.0-3 | 35 | 6.0 x 35.0 | 3 | 3 x 5 | 1.00 x 36 x 4 | 12 | 19.7 | 13.2 | 8.2 | 739 | Configure | | SSP39-6.0-7 | 39 | 6.0 x 39.0 | 7 | 3 x 5 | 1.00 x 36 x 4 | 11.5 | 9.2 | 4.3 | 0.6 | 642 | Configure | | SSP39-6.0-3 | 39 | 6.0 x 39.0 | 3 | 3 x 5 | 1.00 x 36 x 4 | 12 | 13 | 7.4 | 3.1 | 814 | Configure |

|

FINISHES

|

MOUNTING DESIGNATIONS

Tenon Mount

| 2 | 2 3/8'' x 4'' TENON | | 3 | 2 7/8'' x 4'' TENON | | 3.5 | 3 1/2'' x 6'' TENON | | 4 | 4'' x 6'' TENON |

|

Drill Mount

| DM10 | Drilled for 1 Luminaire | | DM2090 | Drilled for 2 Luminaires @ 90º | | DM2180 | Drilled for 2 Luminaires @ 180º | | DM3090 | Drilled for 3 Luminaires @ 90º | | DM4090 | Drilled for 4 Luminaires @ 90º |

|

Open Mount

| OT | Open Top | | OTC | Open Top includes Pole Cap |

|

Gain Mount

| 1GSS4 | (1) CXA | | 2GSS4 | (2) CXA's located on the Same Side | | 3GSS4 | (3) CXA's located on the Same Side | | 4GSS4 | (4) CXA's located on the Same Side | | 2GBB4 | (2) CXA's located Back to Back | | 4GBB4 | (4) CXA's located Back to Back | | 1GSS9 | (1) CXASQ | | 2GSS9 | (2) CXASQ's located on the Same Side | | 3GSS9 | (3) CXASQ's located on the Same Side | | 4GSS9 | (4) CXASQ's located on the Same Side | | 2GBB9 | (2) CXASQ's located Back to Back | | 4GBB9 | (4) CXASQ's located Back to Back |

|

|

OPTIONS

There are numerous options that can be ordered. Please indicate these selections under the options column in the catalog number. Example: CPL-WPR2-BC.

|

|

Accessories

| BC | Base Cover | | CPL | Threaded Coupling* | | NPL | Threaded Nipple* | | WPRP | Festoon Opening** | | LAB | Less Anchor Bolt | | VDI | Vibration Damper Internal |

|

Optional Handholes

| 58HH | 5'' x 8'' Handhole* | | 410HH | 4'' x 10'' Handhole* |

|

Extra Handholes

|

Embedment Pole Options

| E | Embedded Pole | | GS | Ground Sleeve | | CTE | Coal Tar Epoxy |

| | |

| For Embedment Poles: | | Recommended Mounting Height | Recommended Embedment Depth | | Less than 20' | 4' | | 20' - 33' | 6' | | Greater than 33' | 7' |

Greater embedment depths are available upon request.

Embedment poles greater than 35' are not available. |

Additional Simplex

| 1S | 1 @ 0º * | | 2S | 2 @ 180º * | | 3S | 3 @ 90º * | | 4S | 4 @ 90º * |

|

|

* Please advise size, location, and orientation. (Handholes are restricted by size of pole shaft diameter)

** Located 24" above baseplate and same side as handhole. (No electrical included)

|

PACKAGING

Immediately after coating, the lighting standard including the baseplate shall be wrapped in heavy corrugation specially designed and sized to achieve maximum protection in transit.

|

|

KW Industries, Inc. coating process system and stringent quality control procedures provide our customer the finest quality lighting standards in the industry.

|