|

The introduction of applying powder coatings to

lighting standards by  Industries, Inc. changed all the conventional rules. As

a direct result, old technologies such as liquid coatings have become outdated.

Other manufacturers, quick to jump on the powder coating bandwagon, introduced

their formulations and process applications but none have achieved the quality

recognition of the Industries, Inc. changed all the conventional rules. As

a direct result, old technologies such as liquid coatings have become outdated.

Other manufacturers, quick to jump on the powder coating bandwagon, introduced

their formulations and process applications but none have achieved the quality

recognition of the  Coating System. The

components of the unique Coating System. The

components of the unique  Coating System make Coating System make

lighting standards the highest quality available.? lighting standards the highest quality available.?

has no equal; having physical and chemical properties that other

producers of powder coated lighting standards have yet to achieve. has no equal; having physical and chemical properties that other

producers of powder coated lighting standards have yet to achieve.  is

rugged while satisfying the aesthetic demands of the specifier.?? is

rugged while satisfying the aesthetic demands of the specifier.??

|

|

Industries was created exclusively to design and

manufacture lighting standards. Our company's total effort is to provide the

finest lighting standards available in the world. Excellence is the watchword at Industries was created exclusively to design and

manufacture lighting standards. Our company's total effort is to provide the

finest lighting standards available in the world. Excellence is the watchword at

with our with our  Coating System leading the way. There are many variables when selecting a

lighting standard. Design, budget, new technology, craftsmanship and production

considerations are major factors when specifying the grade level and finish of a

lighting standard, In the end, client and specifier agree on one thing...quality

is essential. Coating System leading the way. There are many variables when selecting a

lighting standard. Design, budget, new technology, craftsmanship and production

considerations are major factors when specifying the grade level and finish of a

lighting standard, In the end, client and specifier agree on one thing...quality

is essential.

|

5 YEAR WARRANTY 5 YEAR WARRANTY

10 YEAR WARRANTY 10 YEAR WARRANTY

|

|

powder is

custom formulated from thermosetting polyester resins, curing agents, pigments

and modifiers, to meet specific end-use requirements for durability, chemical

resistance, and UV protection. Resins and pigments are mixed while molten and

then cooled and solidified. The resulting material has a completely uniform

composition. The cooled material is then ground to the desired particle size for

application to the metal. powder is

custom formulated from thermosetting polyester resins, curing agents, pigments

and modifiers, to meet specific end-use requirements for durability, chemical

resistance, and UV protection. Resins and pigments are mixed while molten and

then cooled and solidified. The resulting material has a completely uniform

composition. The cooled material is then ground to the desired particle size for

application to the metal.

Electrostatic Application Offers More

Uniform Coating

Electrostatic

spraying is the most common method for applying powder coatings, and is the method

chosen by  . .

powder is fed pneumatically from

a reservoir to a spray gun where a low amperage, high voltage charge is imparted

to the particles. The parts to be coated are grounded so that the charged

particle will seek the oppositely charged metal surfaces. With this method, a

single application can produce a uniform, monolithic, fusion-bonded

finish. powder is fed pneumatically from

a reservoir to a spray gun where a low amperage, high voltage charge is imparted

to the particles. The parts to be coated are grounded so that the charged

particle will seek the oppositely charged metal surfaces. With this method, a

single application can produce a uniform, monolithic, fusion-bonded

finish.

The powder-coated parts then enter an oven where the resins,

pigments, and other reactive agents crosslink to produce a high molecular weight

binder system, resulting in a tough, durable coating. The mechanical and

physical properties of  are listed in

Figure 1. are listed in

Figure 1.

Superiority

Superiority

was developed for outstanding weatherability,

toughness, and architectural aesthetics. When considering the advantages of the was developed for outstanding weatherability,

toughness, and architectural aesthetics. When considering the advantages of the

powder coating process, it's difficult to understand why anyone would

choose a lighting standard coated with liquid paint. powder coating process, it's difficult to understand why anyone would

choose a lighting standard coated with liquid paint.

?  powder coating is 100% solid with every powder

particle containing the total color system. powder coating is 100% solid with every powder

particle containing the total color system.

? The high molecular weight of

powder coatings provide better corrosion,

impact, chip, and scratch resistance, which means less damage. powder coatings provide better corrosion,

impact, chip, and scratch resistance, which means less damage.

? Adhesion

problems associated with multiple coats of liquid paint are eliminated.

?

There are no runs, sags or drips in  powder

finishes. powder

finishes.

? Paint defects such as solvent popping, pinholes, and blistering

are eliminated, since there are no solvents in powders.

?  is highly resistant to diluted aqueous acids, salts,

aliphatic and aromatic hydrocarbons, solvents, alcohols, grease and

oils. is highly resistant to diluted aqueous acids, salts,

aliphatic and aromatic hydrocarbons, solvents, alcohols, grease and

oils.

? provides UV protection which

eliminates chalking and minimizes color fading. Low molecular weight, liquid

systems simply can't compare with provides UV protection which

eliminates chalking and minimizes color fading. Low molecular weight, liquid

systems simply can't compare with  high

molecular weight powders. Liquid system finishes are easily chipped and

scratched, and require constant care to maintain appearance, and most important,

to prevent corrosive damage. high

molecular weight powders. Liquid system finishes are easily chipped and

scratched, and require constant care to maintain appearance, and most important,

to prevent corrosive damage.

|

|

|

The Superior Internal Coating  is a specially

formulated internal coating used to complete the is a specially

formulated internal coating used to complete the  system. The internal base end of the pole shall be blast cleaned

and powder coated in accordance with external coating requirements for a minimum

distance of 12 inches as measured from the base plate. The remainder of the

internal pole surface shall be coated with system. The internal base end of the pole shall be blast cleaned

and powder coated in accordance with external coating requirements for a minimum

distance of 12 inches as measured from the base plate. The remainder of the

internal pole surface shall be coated with  , a

thermal plastic hydrocarbon resin system specially formulated for application

over untreated steel surfaces. The internal coating shall contain chromate

corrosion inhibitors and be capable of passing 1,000 hours of salt spray

exposure (ASTMB-1 17) in a 5% NaCl solution of 95?F and 95% relative humidity

producing no blistering. , a

thermal plastic hydrocarbon resin system specially formulated for application

over untreated steel surfaces. The internal coating shall contain chromate

corrosion inhibitors and be capable of passing 1,000 hours of salt spray

exposure (ASTMB-1 17) in a 5% NaCl solution of 95?F and 95% relative humidity

producing no blistering.

The  shall be

applied to the internal surfaces at a substrate temperature of 185?F to 212?F

insuring intimate migration through, and encapsulation of, the surface oxide

film. shall be

applied to the internal surfaces at a substrate temperature of 185?F to 212?F

insuring intimate migration through, and encapsulation of, the surface oxide

film.  shall be applied in a manner to insure

complete, uniform I.D. coverage to a thickness 3-5 mils. shall be applied in a manner to insure

complete, uniform I.D. coverage to a thickness 3-5 mils.  shall overlap the internal powder coated portion of

the pole a minimum of 6 inches. shall overlap the internal powder coated portion of

the pole a minimum of 6 inches.

is

specifically designed as an internal coating to resist atmospheric and other

normally encountered corrosive media. The film shall remain soft and will

exhibit film appearance or texture common to external coating systems. The

mechanical and physical properties of is

specifically designed as an internal coating to resist atmospheric and other

normally encountered corrosive media. The film shall remain soft and will

exhibit film appearance or texture common to external coating systems. The

mechanical and physical properties of  are

listed in Figure 2. are

listed in Figure 2.

Special preparation of the metal, formulation of the powder, and sophisticated application techniques make it the most durable, resilient, tightly bonded, colorfast pole finish available. That makes  Coating System lighting standards practically maintenance-free and cost effective. Coating System lighting standards practically maintenance-free and cost effective.

5 YEAR WARRANTY

Metal Preparation

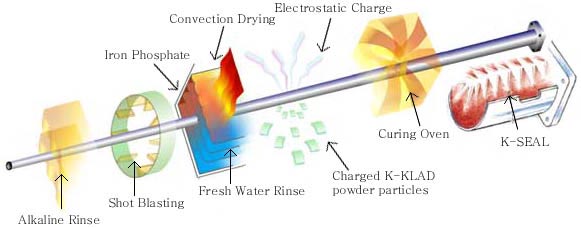

The exterior surface is cleaned with an alkaline rinse to remove dirt, oil or surface contaminants. The exterior metal surface is then blasted with a combination of shot and grit, to remove all mill scale, oxides, or any foreign matter. Excess shot and by-products from the blasting operation are blown off with dry, compressed air. Blasting in accordance with the above requirements provides a 1.5 mil profile anchor pattern for a maximum fusion bond to the substrate. This surface satisfies the "near white" specification as published by the Steel Structures Painting Council Standards SSPC-SP10 (near white).

Chemical Pretreatment

The blasted metal surface is chemically pretreated with an iron phosphate conversion coating applied at high pressure at 110? to 120?F. The preheated surface immediately receives an ambient fresh water rinse containing special surfactants and sealers. The phosphated exterior metal surface is force dried by convection heat at approximately 200?F., forming a dry tight micro-crystalline coating not less than 50mg./sq.ft. of iron phosphate on the surface.

Powder Coating

is a special powder coating formulated from a unique combination of polyester resins designed to exhibit superior outdoor weatherability, durability and gloss retention. is a special powder coating formulated from a unique combination of polyester resins designed to exhibit superior outdoor weatherability, durability and gloss retention.  is applied with state-of-the-art electrostatic powder coating equipment to a uniform 8 mil finish. Charged powder particles adhere to the surface of the lighting standard to form a high molecular weight, fusion-bonded finish. Precisely controlled bake times and temperatures ensure complete bonding and dispersion of pigments and resins. is applied with state-of-the-art electrostatic powder coating equipment to a uniform 8 mil finish. Charged powder particles adhere to the surface of the lighting standard to form a high molecular weight, fusion-bonded finish. Precisely controlled bake times and temperatures ensure complete bonding and dispersion of pigments and resins.

Internal Coating Internal Coating

The internal base-end of the pole is blasted, cleaned and powder coated for a minimum of 12 inches from the baseplate. The entire internal surfaces including powder coated area at the base-end are coated with  , a thermoplastic hydrocarbon resin system specially formulated for application over untreated steel surfaces. , a thermoplastic hydrocarbon resin system specially formulated for application over untreated steel surfaces.  is to be applied in a manner to ensure complete, uniform ID coverage to a thickness of 3 mils. The internal coating contains special corrosion inhibitors and is capable of passing 1000 hours of salt spray exposure (ASTM B-117). is to be applied in a manner to ensure complete, uniform ID coverage to a thickness of 3 mils. The internal coating contains special corrosion inhibitors and is capable of passing 1000 hours of salt spray exposure (ASTM B-117).

Over Hot Dip Galvanizing Over Hot Dip Galvanizing

10 YEAR WARRANTY

In areas where superior performance is required,  powder coating applied over hot dip galvanized steel provides an additional surface barrier, encapsulating the cathodic protective zinc surface. powder coating applied over hot dip galvanized steel provides an additional surface barrier, encapsulating the cathodic protective zinc surface.

Hot Dip Galvanizing

The exterior and interior metal surface is hot dip galvanized in accordance with ASTM A-123. During the hot dip galvanizing process the molten zinc reacts with the steel surface forming a barrier that becomes an extension of the steel surface.

Metal Preparation

The exterior galvanized surface is washed under heat and pressure with an alkaline rinse to remove any excess oxides or contaminants. The exterior surfaces are then centrifugally brush blasted with a combination of shot and grit to remove excess oxides and foreign matter providing an anchor pattern profile without disruption to the galvanized surface.

Chemical Pretreatment

The blasted metal surface is chemically pretreated with an iron phosphate conversion coating applied at high pressure at 110? to 120?F. The preheated surface immediately receives an ambient fresh water rinse containing special surfactants and sealers. The phosphated exterior metal surface is force dried by convection heat at approximately 200?F., forming a dry tight micro-crystalline coating not less than 50 mg./sq.ft. of iron phosphate on the surface.

Powder Coating

Charged powder particles are applied to the surface of the lighting standard to form a high molecular weight, fusion bonded  finish. Exact bake times and temperatures ensure complete bonding and dispersion of pigments and resins. This process assures superior weatherability, durability and gloss retention. finish. Exact bake times and temperatures ensure complete bonding and dispersion of pigments and resins. This process assures superior weatherability, durability and gloss retention.

Internal Coating Internal Coating

The internal galvanized section is coated with  , a corrosion inhibitor, to form a protective internal barrier. The cathodic protection of the hot dip galvanized surface, encapsulated by the , a corrosion inhibitor, to form a protective internal barrier. The cathodic protection of the hot dip galvanized surface, encapsulated by the  internal coat, provides superior corrosion resistance. internal coat, provides superior corrosion resistance.

Fused Powder Coating performance Specifications Fused Powder Coating performance Specifications

(based on phosphate coated panels)

GLOSS: ASTM D-523-60 deg 50% to 60% gloss

PENCIL HARDNESS: ASTM D-3363-2H minimum

IMPACT RESISTANCE: ASTM D-2794-160 inch lbs. forward/reverse

FLEXIBILITY: ASTM D-522-180 deg bend over 1/4" mandrel

ADHESION: ASTM D-3359B - no lifting of coating

SALT SPRAY RESISTANCE: ASTM B-117-1000 hrs. in 5% solution at 95?F and 95% relative humidity produces no blistering and less than 1/16" undercutting from scribe

HUMIDITY RESISTANCE: ASTM D-2247-100% relative humidity at 100F for 1000 hours-no effect

WEATHERABILITY: ASTM D-822-1 year south Florida exposure at 45? angle 91% of gloss retention

|

|

Am cause I love hair bundles uk and after washing full lace wigs uk a spray detangler and bio silk very small amounts my edges needed done wore 2 months. It is really good hair. But I think lace wigs uk would be kind of hard for microbraids. You can also use thongs for lace front wigs uk gives great curls. Depending on how well you take care of it. It should last you a long time. My last me me but I usually never reuse so I end up throwing lace wigs away. Klaiyi Hair sell all kinds of virgin human hair weave bundles, lace closure, lace frontal closure, wig with various hair texture, lace wigs uk loose wave, jerry curly. |

|

| | | | | Copyright © 2026 KW Industries, Inc. All rights reserved.

|

|