|

| Roadway Lighting Standards with Upsweep Arm

|

|

Pole Shaft

The pole shaft is one or two section design, each section being fabricated from

standard 11 gauge (0.1196"), 7 gauge (0.1793"), or 3 gauge (0.2391") steel. The

pole shaft material is a weldable grade hot rolled commercial quality carbon

steel with a guaranteed minimum yield strength of 55,000 psi after fabrication.

Each section is one-piece construction with a full length longitudinal weld and

is cylindrical in cross-section having a uniform taper of 0.14 inches of

diameter change per foot of length.

|

Base Plate

The anchor base is fabricated from structural quality hot rolled carbon steel

plate that meets or exceeds a minimum yield strength of 36,000 psi. The anchor

base telescopes the pole shaft and is circumferentially welded top and bottom.

All welds are performed in accordance with the American Welding Society

specification AWS D1.1, latest edition.

|

Anchor Bolts

Anchor bolts are fabricated from commercial quality hot rolled carbon steel bar

that meets or exceeds a minimum yield strength of 55,000 psi. Four properly

sized anchor bolts, each with two regular hex nuts and washers, are furnished

and shipped with all poles unless otherwise specified. Anchor bolts shall have

the threaded end galvanized a minimum of 8 inches in accordance with ASTM

A-153. Fully galvanized anchor bolts are available upon request.

|

Handhole

An oval reinforced gasketed handhole, having a nominal 3" x 5" or 4" x 6-1/2"

inside opening, located 1'-6" above base, is standard on all poles. Optional 5"

x 8" and 4" x 10" handholes are available (see options). A grounding location

is provided inside the handhole ring.

|

Finishes

The

Standard Finish is a polyester thermosetting powder coating applied to

the surface of the substrate to a minimum of 3 mils for all color finishes.

Hot dip Galvanized finish to a ASTM A-123 specification or primed

finish is also available. For optional finishes, see

K-KLAD and

K-KLAD Over Galvanizing.

|

Design

All KW Industries, Inc. Roadway Lighting Standards (RTS) and luminaire arms

meet or exceed all American Association of State Highway and Transportation

Officials (AASHTO) wind loading specifications for roadway standards.

|

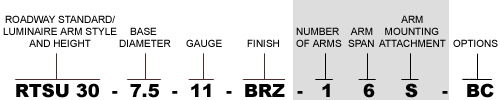

HOW TO ORDER

When ordering KW Roadway Lighting Standards (RTS), luminaire arms and

accessories, be sure to specify the complete catalog number. Our catalog

numbers reflect the precise specifications of the item ordered to ensure our

customers will receive the product which meets their exact requirements.

The following explanation of the catalog numbers will be helpful in placing

orders:

|

CATALOG LOGIC - ORDERING SAMPLE

|

|

Catalog Number

|

Mounting

Height

|

Base

Diameter

|

Gauge

|

Handhole

Size

|

Anchor Bolt

|

Bolt

Circle

|

Ship

WT.

|

| RTSU20-6.1-11 | 20 | 6.1 | 11 | 3 x 5.0 | 0.75 x 30 x 3 | 9.5 | 149 | | RTSU20-6.5-11 | 20 | 6.5 | 11 | 4 x 6.5 | 1.00 x 36 x 4 | 9.5 | 205 | | RTSU25-6.1-11 | 25 | 6.1 | 11 | 3 x 5.0 | 0.75 x 30 x 3 | 9.5 | 173 | | RTSU25-6.5-11 | 25 | 6.5 | 11 | 4 x 6.5 | 0.75 x 30 x 3 | 9.5 | 204 | | RTSU25-6.8-11 | 25 | 6.8 | 11 | 4 x 6.5 | 0.75 x 30 x 3 | 10 | 190 | | RTSU25-7.0-11 | 25 | 7.0 | 11 | 4 x 6.5 | 1.00 x 36 x 4 | 10 | 230 | | RTSU25-7.5-11 | 25 | 7.5 | 11 | 4 x 6.5 | 1.00 x 36 x 4 | 10.5 | 265 | | RTSU30-6.8-11 | 30 | 6.8 | 11 | 4 x 6.5 | 0.75 x 30 x 3 | 10 | 213 | | RTSU30-7.0-11 | 30 | 7.0 | 11 | 4 x 6.5 | 1.00 x 36 x 4 | 10 | 253 | | RTSU30-7.5-11 | 30 | 7.5 | 11 | 4 x 6.5 | 1.00 x 36 x 4 | 10.5 | 265 | | RTSU30-8.0-11 | 30 | 8.0 | 11 | 4 x 6.5 | 1.00 x 36 x 4 | 11 | 293 | | RTSU35-7.5-11 | 35 | 7.5 | 11 | 4 x 6.5 | 1.00 x 36 x 4 | 10.5 | 283 | | RTSU35-8.0-11 | 35 | 8.0 | 11 | 4 x 6.5 | 1.00 x 36 x 4 | 11 | 311 | | RTSU35-8.5-11 | 35 | 8.5 | 11 | 4 x 6.5 | 1.00 x 36 x 4 | 11.5 | 338 | | RTSU35-9.0-11 | 35 | 9.0 | 11 | 4 x 6.5 | 1.00 x 36 x 4 | 12.5 | 358 | | RTSU40-10.0-11 | 40 | 10.0 | 11 | 4 x 6.5 | 1.00 x 36 x 4 | 13.5 | 480 | | RTSU40-9.0-11 | 40 | 9.0 | 11 | 4 x 6.5 | 1.00 x 36 x 4 | 12.5 | 376 | | RTSU40-9.0-7 | 40 | 9.0 | 7 | 4 x 6.5 | 1.25 x 42 x 6 | 12.5 | 597 |

|

|

RTSU

SINGLE ARM LUMINAIRES

|

| ARM |

WIND |

RTSU 20 |

RTSU 25 |

RTSU 30 |

RTSU 35 |

RTSU 40 |

| 14S |

80 |

20-6.1-11

20-6.5-11 |

25-6.1-11

25-7.0-11 |

30-6.8-11

30-7.0-11

30-7.5-11

30-8.0-11 |

35-7.5-11

35-8.0-11

35-8.5-11 |

40-9.0-11 |

| 90 |

20-6.1-11

20-6.5-11 |

25-6.1-11

25-7.0-11 |

30-6.8-11

30-7.0-11

30-7.5-11

30-8.0-11 |

35-7.5-11

35-8.0-11

35-8.5-11 |

40-9.0-11 |

| 100 |

20-6.1-11

20-6.5-11 |

25-6.1-11

25-7.0-11 |

30-6.8-11

30-7.0-11

30-7.5-11

30-8.0-11 |

35-7.5-11

35-8.0-11

35-8.5-11 |

40-9.0-11 |

| 16S |

80 |

20-6.1-11

20-6.5-11 |

25-6.1-11

25-7.0-11 |

30-6.8-11

30-7.0-11

30-7.5-11

30-8.0-11 |

35-7.5-11

35-8.0-11

35-8.5-11 |

40-9.0-11 |

| 90 |

20-6.1-11

20-6.5-11 |

25-6.1-11

25-7.0-11 |

30-6.8-11

30-7.0-11

30-7.5-11

30-8.0-11 |

35-7.5-11

35-8.0-11

35-8.5-11 |

40-9.0-11 |

| 100 |

20-6.1-11

20-6.5-11 |

25-6.1-11

25-7.0-11 |

30-7.5-11

30-8.0-11 |

35-7.5-11

35-8.0-11

35-8.5-11 |

40-9.0-11 |

| 18S |

80 |

20-6.1-11

20-6.5-11 |

25-6.1-11

25-7.0-11 |

30-6.8-11

30-7.0-11

30-7.5-11

30-8.0-11 |

35-7.5-11

35-8.0-11

35-8.5-11 |

40-9.0-11 |

| 90 |

20-6.1-11

20-6.5-11 |

25-6.1-11

25-7.0-11 |

30-6.8-11

30-7.0-11

30-7.5-11

30-8.0-11 |

35-7.5-11

35-8.0-11

35-8.5-11 |

40-9.0-11 |

| 100 |

20-6.1-11

20-6.5-11 |

25-6.1-11

25-7.0-11 |

30-7.5-11

30-8.0-11 |

35-7.5-11

35-8.0-11

35-8.5-11 |

40-9.0-11 |

RTSU

DOUBLE ARM LUMINAIRES

|

| ARM |

WIND |

RTSU 20 |

RTSU 25 |

RTSU 30 |

RTSU 35 |

RTSU 40 |

| 24S |

80 |

20-6.1-11

20-6.5-11 |

25-6.1-11

25-6.5-11

25-7.0-11 |

30-7.0-11

30-7.5-11

30-8.0-11 |

35-8.0-11

35-8.5-11

35-9.0-11 |

40-9.0-11

40-10.0-11 |

| 90 |

20-6.1-11

20-6.5-11 |

25-6.8-11

25-7.0-11 |

30-7.0-11

30-7.5-11

30-8.0-11 |

35-8.0-11

35-8.5-11

35-9.0-11 |

40-10.0-11

40-9.0-7 |

| 100 |

20-6.1-11

20-6.5-11 |

25-7.0-11

25-7.5-11 |

30-7.5-11

30-8.0-11 |

35-8.5-11

35-9.0-11 |

40-10.0-11

40-9.0-7 |

| 26S |

80 |

20-6.1-11

20-6.5-11 |

25-6.1-11

25-6.5-11 |

30-7.0-11

30-7.5-11

30-8.0-11 |

35-8.0-11

35-8.5-11

35-9.0-11 |

40-9.0-11

40-10.0-11 |

| 90 |

20-6.1-11

20-6.5-11 |

25-6.8-11

25-7.0-11 |

30-7.0-11

30-7.5-11

30-8.0-11 |

35-8.5-11

35-9.0-11

35-10.0-11 |

40-10.0-11

40-9.0-7 |

| 100 |

20-6.1-11

20-6.5-11 |

25-7.0-11

25-7.5-11 |

30-7.5-11

30-8.0-11 |

35-9.0-11

35-10.0-11 |

40-9.0-7 |

| 28S |

80 |

20-6.1-11

20-6.5-11 |

25-6.8-11

25-7.0-11 |

30-7.0-11

30-7.5-11

30-8.0-11 |

35-8.0-11

35-8.5-11

35-9.0-11 |

40-10.0-11

40-9.0-7 |

| 90 |

20-6.1-11

20-6.5-11 |

25-7.0-11

25-7.5-11 |

30-7.5-11

30-8.0-11 |

35-8.5-11

35-9.0-11

35-10.0-11 |

40-10.0-11

40-9.0-7 |

| 100 |

20-6.5-11

20-6.8-11 |

25-7.0-11

25-7.5-11 |

30-7.5-11

30-8.0-11 |

35-9.0-11

35-10.0-11 |

40-9.0-7 |

|

Breakaway Bases

Note: For existing A.B. wth B.C. (10-1/2" - 12-15/16"), consult factory for modified transformer-base.

|

Breakaway Support Couplings

|

FINISHES

|

OPTIONS

There are numerous options that can be ordered. Please indicate these

selections under the options column in the catalog number. Example: WPR2-NC.

|

|

Accessories

| BC | Base Cover | | NC | Nut Covers | | WPRP | Festoon Opening** | | LAB | Less Anchor Bolt | | VDI | Vibration Damper Internal |

|

Optional Handholes

| 58HH | 5'' x 8'' Handhole* | | 410HH | 4'' x 10'' Handhole* |

|

Extra Handholes

|

Embedment Pole Options

| E | Embedded Pole | | GS | Ground Sleeve | | CTE | Coal Tar Epoxy |

| | |

| For Embedment Poles: | | Recommended Mounting Height | Recommended Embedment Depth | | 20' - 35' | 5' | | 35' - 40' | 7' |

Greater embedment depths are available upon request. |

|

* Please advise size, location, and orientation. (Handholes are

restricted by size of pole shaft diameter)

** Located 24" above baseplate and same side as handhole. (No electrical included)

|

|